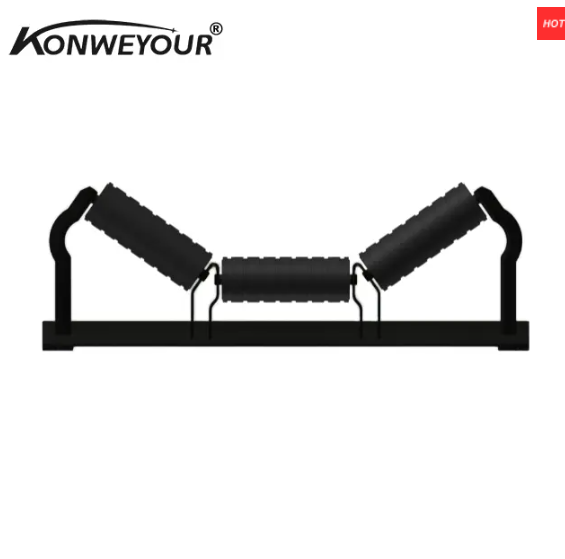

Nneɛma a wɔde fa tubular belt so a wɔde ahyɛ mu .

Tubular belt conveyor a wɔato mu no yɛ conveying nhyehyɛe foforo a wɔayɛ ama nneɛma a ɛyɛ fɛ a ɛho tew, ɛyɛ adwuma yiye, na ɛnyɛ nea atwa yɛn ho ahyia ho asɛm kɛse. Ne tubular nhyehyɛe a wɔato mu koraa no siw nneɛma a ɛbɛhwie agu, mfutuma a ɛba, ne efĩ, na ɛma ɛyɛ nea eye ma nnwuma a ɛhwehwɛ sɛ wɔbɔ nneɛma a atwa yɛn ho ahyia ho banbɔ ne ahotew ho gyinapɛn a emu yɛ den.

Saa conveyor nhyehyɛe yi yɛ nea wotumi sesa no yiye ma ɛyɛ nhyehyɛe a ɛyɛ den, a akwan a ɛda fam, ɛkɔ soro, ne akwan a ɛkɔ akyiri ka ho, na ɛma wotumi fa asase a ɛyɛ den ne mmeae a wɔatoto mu. Belt a ɛyɛ mmerɛw no yɛ tube shape bere a ɛreyɛ adwuma no, na ɛhwɛ ma nneɛma no sen yiye na ɛyɛ adwuma yiye bere a ɛtew nneɛma a wɔsɛe no so no.

Nneɛma atitiriw a ɛwɔ mu .

Nsusuwii a wɔato mu koraa: Esiw mfutuma, nsu a ɛbɛhwie agu, ne nneɛma a ɛyera ano, na ɛma ɛyɛ adwuma yiye.

Versatile routing: Ɛboa horizontal, vertical, ne curved conveying ma layout a ɛyɛ mmerɛw kɛse.

Nneɛma a wɔde di dwuma brɛoo: Ɛyɛ papa ma nneɛma a ɛyɛ mmerɛw bere a ɛtew nkɛntɛnso ne ɔsɛe so bere a wɔde rekɔ no.

Ahoɔden a wɔde di dwuma yiye: wɔayɛ no yiye ama ahoɔden a wɔde di dwuma a ɛba fam ne throughput a ɛkɔ soro wɔ akyirikyiri.

Ɔdansi a ɛtra hɔ kyɛ: Wɔde nneɛma a ɛkorɔn a wɔde bɛtra hɔ akyɛ na wɔde ayɛ adwuma a wotumi de ho to so na esii.

Applications .

a ɛyɛ pɛpɛɛpɛ ma nnwuma te sɛ mining, semɛnte, kuayɛ, aduan a wɔyɛ, anyinam ahoɔden mfiri, ne nnuru a wɔde yɛ nneɛma a nneɛma a atwa yɛn ho ahyia ho banbɔ ne nneɛma a wɔde di dwuma kɛse a ahobammɔ wom ho hia kɛse.

Nneɛma a wɔde yɛ adwuma no mu mfaso: tubular belt conveyor a wɔato mu .

Nneɛma a wɔayɛ no yiye, nneɛma a atwa yɛn ho ahyia ho asɛm ne nea etu mpɔn kɛse .

Sɛ conveyor belt no yɛ adwuma a, ɛyɛ tubular structure, a ɛsi nneɛma a ɛbɛhwie agu, mfuturo a ɛbɛtɔ ne nneɛma a atwa yɛn ho ahyia a ɛbɛsɛe no ano yie, na ɛdi nneɛma a atwa yɛn ho ahyia ho banbɔ ho ahwehwɛdeɛ so.

Nsiesiei no yɛ nea ɛyɛ mmerɛw na wotumi sesa no ma ɛne adwumayɛ tebea a ɛyɛ den hyia .

Ebetumi anya kwan a ɛkɔ soro, ɛkɔ soro ne nea ɛwɔ afã horow pii a ɛkɔ akyiri, a ɛnyɛ den sɛ ɛbɛfa mmeae a ɛyɛ teateaa ne asase a ɛyɛ den so.

Nneɛma a wɔde fa nneɛma mu a ɛyɛ mmerɛw, ɛbɔ ho ban .

Tubular structure no brɛ nneɛma a ɛwɔ hɔ no nkɛntɛnso ne sɛnea ɛsɛe no ase bere a wɔreyɛ nneɛma no, na ɛfata titiriw ma nneɛma a ɛyɛ granular, powder anaa mmerɛw a wɔde fa.

ahoɔden a wɔkora so na etu mpɔn kɛse .

Nneɛma a wɔayɛ no yiye no ma ahoɔden a wɔde di dwuma no so tew, ɛboa akwantu a ɛkɔ akyiri ne nea ɛma nneɛma kɔ so kɛse, na ɛma nneɛma a wɔyɛ no yɛ adwuma yiye.

Ɔdan no yɛ nea ɛtra hɔ kyɛ na ɛnyɛ den sɛ wobɛhwɛ so .

Wɔde nneɛma a ahoɔden wom kɛse na ɛyɛe, na ɛyɛ nea ɛko tia, a ɛko tia nsɛe, ɛwɔ nkwa nna tenten ne ɛka a wɔbɔ wɔ nsiesie ho a ɛba fam.

Nneɛma a wɔde di dwuma wɔ ɔkwan a ɛtrɛw so .

Wɔde di dwuma kɛse wɔ nnwuma te sɛ nneɛma a wotu fi fam, nneɛma a wɔde si adan, semɛnte, tumi, nnuru a wɔde yɛ nneɛma, ne aburow a wɔyɛ mu.